We are offering new or used Oilfield Equipment : Frac Pumps, Frac Blenders, Sand Kings, Data Vans, Twin or Single Pump Skids, Containers or Trailers, Nitrogen and Wireline Units and many other.

Let us know what you would need, and our people will direct you to the right Equipment.

Ask for a quote

Feel free to contact us for Oilfield new or used Equipment.

POWER ENDS and FLUID ENDS for SALE

KATT GmbH, has various Fluid Ends and Power Ends for Sale (TWS 2250 and QWS 2500) out of following locations:

Germany, Ukraine, Romania.

POWER ENDS AND FLUID ENDS FOR SALE

VARIOUS POWER ENDS AND FLUID ENDS AVAILABLE FOR SALE IN EUROPE.

Frac Pumping Unit 2250 BHP

The Stewart & Stevenson Model FT2251T High Pressure Pump is a trailer mounted fracturing unit capable of pumping inhibited acid and other proppant laden stimulation in harsh oilfield environments

The FT-2251T is remotely operated from the U-DAC or alternatively a suitcase control box. This unit is capable of operating in an ambient temperature range of -40°C to +50°C. The deck engine is capable of delivering 2250 BHP to the engine flywheel at SAE conditions and the pump is capable of delivering 2000 HHP.

Engine Hrs : <200

Pump Hrs : <500

MAIN COMPONENTS

- Tandem (two) Axle fixed gooseneck, “single drop” Trailer

- Diesel Engine: MTU 12V 4000 S83, rated 225 BHP

- Transmission Type: Allison S9820

- High Pressure Pump TWS 2250 Triplex. 4.5″ or 5.0" Plunger

AVAILABILITY

Multiple Frac Pumps available for sale in Europe.

DIMENSIONS

- Lenght : 13100mm

- Width : 2550mm

- Height : 3850mm

- Weight : 28050 kg

UNIT FOR SALE

MULTIPLE UNITS AVAILABLE IN EUROPE.

Frac Blender

The Stewart & Stevenson MT-132HP is a trailer-mounted 128 bbl/min fracturing blender designed to mix slurries for fracturing treatments and providing boost pressure.

Blender MT-132 is capable of handling a wide array tasks associated with complex fracturing operations in harsh oilfield conditions. The unit is capable of operating in temperature ranges from -40°C to 46°C. Maximum proppant load is equal to 24 000 pounds per minute and maximum concentration is equal to 20 PPA (2 400 kg/m3).

MAIN COMPONENTS

- Front Deck Diesel Engine: CAT C18, rated 755 BHP For the Hydraulic system

- Rear Deck Diesel Engine: CAT C18, rated 800 BHP for the centrifugal discharge pump

- Suction Pump : Gorman-Rupp 12"x12"

- Discharge Pump : Mission Magnum 14"x12" XP

- Liquid chemical additive system : Five Chemical Injection system

- Dry chemical additive system : Two Variable speed, hydraulically driven, stainless steel, dry additive feeders

AVAILABILITY

Multiple Frac Pumps available for sale in Europe.

DIMENSIONS

- Lenght : 14000mm

- Width : 2500mm

- Height : 4000mm

UNIT FOR SALE

MULTIPLE UNITS AVAILABLE IN EUROPE.

Hydration Unit

The Stewart & Stevenson Model CT-5CAS/HYD is a trailer-mounted hydration unit designed to hydrate oilfield gel and add fracturing chemicals for use in fracturing fluid operations.

Hydration CT-5CAS is equipped with 200 bbl tank and five lines using to pump liquid chemical additives. Water enters the unit through an inlet manifold. Also, the inlet manifold provides a high-rate polymer gel injection port. The water/gel slurry is pumped into the hydration tank through a magnetic flowmeter and through a backup turbine flowmeter via 12’’ X 12’’ centrifugal pump. The hydration tank is a multi-chamber, mixing vessel, with an alternating over/under torture path. The tank includes mixing paddles to eliminate ’’dead zones’’ and increase fluid shear. The unit is capable of operating in temperature ranges from -40°C to 46°C.

MAIN COMPONENTS

- Tandem (two) Axle fixed gooseneck, “single drop” Trailer

- Diesel Engine: CAT Tier IV, rated 755 BHP;

- Hydraulic system : Complete Hydraulic system

- Chemical Pumping system : Roper and Waukeshka.

- Centrifugal pump : Gorman-Rupp 12"x12"

- A more detailed Technical description will be given on request.

AVAILABILITY

Multiple Hydration Units available for sale in Europe.

DIMENSIONS

- Lenght : 14000mm

- Width : 2500mm

- Height : 4000mm

UNIT FOR SALE

MULTIPLE UNITS AVAILABLE IN EUROPE.

Frac Dry Hydration Unit

MAIN COMPONENTS

- Diesel Engine: Detroit Diesel Series 60; 665 hp

- Suction and Recirculation Pump : Gorman-Rupp

- Flowmeters : Rosemount MID

- LAS Pump : Continental pump

- A more detailed Technical description will be given on request.

AVAILABILITY

One Hydration Unit available for sale in Europe.

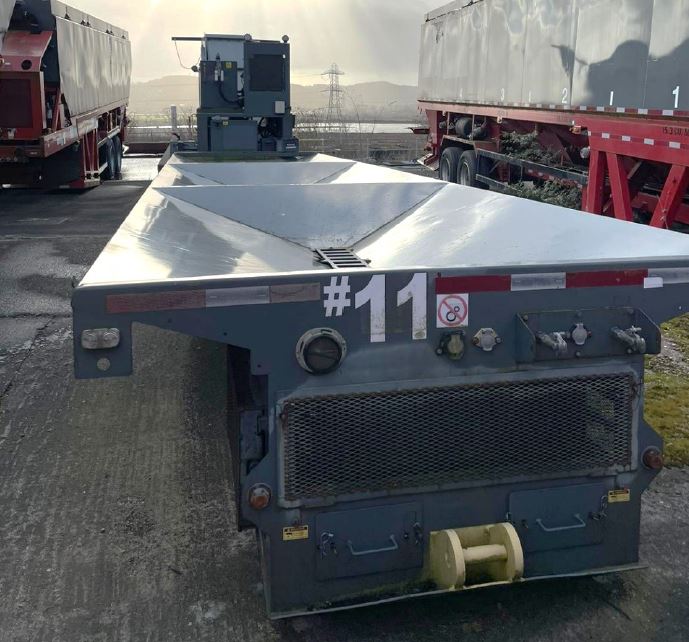

Manifold Trailer

The C.A.T. Construction (actual GOES GmbH) Manifold Trailer is a portable manifold designed for use in oilfield stimulation and related services. The unit consists of suitable suction and discharge connections and valves for up to fourteen (14) frac pumpers and two (2) blenders. The manifold is designed for frac use.

MAIN COMPONENTS

- The trailer is a rock-over, tandem axle design used to transport the fracturing manifold only

Low Pressure Suction Manifold

- - 4 connections 4" for Blender Discharge

- - 6 connections 6" for Blender Discharge

- - 2 connections 8" for Frac Pump Suction

- - 28 connections 4" discharge ports, 14 per side

High Pressure Discharge Manifold

- - Primary Flow Line : 2 x 4" - 15K Safety Iron

- - Inlet Branch Typpe : Lateral 4” – 15K Safety Iron with 3” 1502 F Hammer union5K

- - Frac Pumper Inlet : Inlet Branch at Primary 3"-15K Female; Inlet Swing Arm : Swivel Assy 3” – 15K Style 10 MxF Pup Joint 3” – 15K 4ft MxF

- - Manifold Discharge : 4 X-over from 4” 1502 to 4” 1002

AVAILABILITY

Two Units available for sale in Europe.

DIMENSIONS

- Lenght : 15000mm

- Width : 2550mm

- Height : 3000mm

UNIT FOR SALE

TWO UNITS AVAILABLE IN EUROPE.

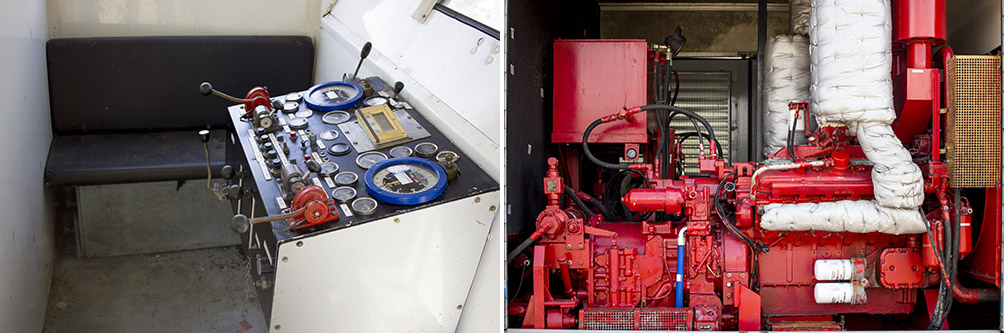

Frac Data Acquisition Center

The Steward & Stevenson Model ET-26ACD is a trailer-mounted control and data acquisition centre capable of operating in harsh oilfield environments. The unit provides operators an environmentally controlled area to control and monitor well treatments.

The unit is designed to operate fracturing pumps, blenders, the LAS unit, the Hydration unit, and acquire data in real-time. The computers have also been outfitted with control and DAS software. Capable of operating in an ambient temperature range of -40°C to 46°C, and ability to be transported over non-grade road surfaces in the often rough environments found in the oilfield make this Data Van the keystone of Fracturing operation. Fracturing Data Van offers remote data transmitting services via satellite (data plan not included). All fracturing jobs can be viewed in real time from any computer with an internet connection.

MAIN COMPONENTS

Power supply

- U-DAC is powered by a20 kW generator driven by diesel engine

- U-DAC can be supplied by an external source (voltage: 220 V, 50 Hz)

- U-DAC can be supplied by emergency mode UPS (30 min)

Software

- AccuFracTM (data capture, blender, hydration unit, control of chemical additives)

- Intelligent Pump Control system (IPC-PC TM)

- Emergency computer

- 13 LCD monitors for above software

- Optionally: Instead of S&S IPC, the Prime MPC software can be provided for Geschäftsführer: Handelsregister: Bank: Seite/Page 2/4 Amtsgericht Hildesheim • HRB 200611 Commerzbank AG Henning Bartels St-Nr/ Tax-No..: 23 190 19 209002268 BIC: COBADEFFXXX Volker Hein USt-ID/VAT-ID: DE 252 562 054 IBAN: DE21 2578 0022 0417 6790 00 controlling the Frac Pumps. See pictures

AVAILABILITY

One Unit available for sale in Europe.

DIMENSIONS

- Lenght : 8700mm

- Width : 2600mm

- Height : 3900mm

UNIT FOR SALE

ONE UNIT AVAILABLE IN EUROPE.

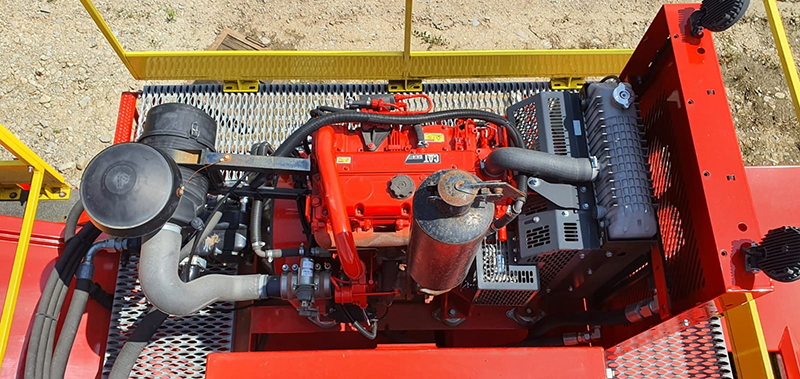

Sand Mover (Sand King SK 3000)

Convey-All Sand Mover model SK-3000-ACSEU is a trailer-mounted unit designed to store and deliver proppant during hydraulic fracturing treatments.

The unit is equipped with five compartments allow loading of 62.5 m3 of bulk material (equal to 100 tons of proppant). Each of the compartments has an inlet hatch located on the top of the unit and two 3’’ type FB connections. Complete unloading of each compartment is possible, thanks to remotely controlled hydraulic valves on the bottom of the unit. Proppant is moved in the direction of the blender by the belt conveyor which allows for transfer of the material at a speed of 15 000 lbs/min (~7 tons/min). The Sand Mover is equipped with a scale. Readings are displayed on the unit and in the U-DAC.

MAIN COMPONENTS

- Deck Engine: CAT C4-4, rated 130 BHP

- Efficiency : The rate of bulk material transfer - 15000 lbs/min (~7 tons/min)

- Support System : Sand Mover has four independently controlled supports allowing for the safe placement on the ground.

- Weight’s measurement : The unit is equipped with a scale showing the contents of stored material with an accuracy of 50 kg

- Compartments : Sand Mover has five independently compartments; Each compartment has an independent valve controlled by the operator

AVAILABILITY

Multiple Units available for sale in Europe.

DIMENSIONS

- Lenght : 15850mm

- Width : 2540mm

- Height : 4000mm

UNIT FOR SALE

MULTIPLE UNITS AVAILABLE IN EUROPE.

Sand Mover (Sand King SK 2000)

Convey-All Sand Mover model SK-2000-ACSEU is a trailer-mounted unit designed to store and deliver proppant during hydraulic fracturing treatments.

The unit is equipped with four compartments that allow to load 45.6 m3 of bulk material (equal to 80 tons of proppant). Each of the compartments has an inlet hatch located on the top of the unit and two 3’’ type FB connections. Complete unloading of each compartment is possible, thanks to remotely controlled hydraulic valves on the bottom of the unit. Proppant is moved in the direction of the blender by the belt conveyor which allows for transfer of the material at a speed of 15 000 lbs/min (~7 tons/min). The Sand Mover is equipped with a scale. Readings are displayed on the unit and in the U-DAC.

MAIN COMPONENTS

- Deck Engine: CAT C4-4, rated 130 BHP

- Efficiency : The rate of bulk material transfer - 15000 lbs/min (~7 tons/min)

- Support System : Sand Mover has four independently controlled supports allowing for the safe placement on the ground.

- Weight’s measurement : The unit is equipped with a scale showing the contents of stored material with an accuracy of 50 kg

- Compartments : Sand Mover has five independently compartments; Each compartment has an independent valve controlled by the operator

AVAILABILITY

Multiple Units available for sale in Europe.

DIMENSIONS

- Lenght : 12530mm

- Width : 2530mm

- Height : 3910mm

UNIT FOR SALE

MULTIPLE UNITS AVAILABLE IN EUROPE.

All Belt Conveyor - Unibelt 1800

Convey-All Belt Conveyor Model Unibelt-1800 is a trailer-mounted fracturing unit designed to deliver proppant from sand movers to blender.

A single belt conveyor (Unibelt) is a unit which is used in the situation of multi-stage hydraulic fracturing. It happens when the amount of required proppant is greater than possibility of its storage in the SK-2000 or SK-3000 Sand Movers. Belt conveyor is powered by Caterpillar Diesel Engine Model C4-4 and allows to move the proppant at speeds up to 15 000 lbs/min (~7 tons/min).

MAIN COMPONENTS

- Deck Engine: CAT C4-4, rated 130 BHP

- Efficiency : The rate of bulk material transfer - 15000 lbs/min (~7 tons/min)

- Support System : Single Belt Conveyorr has four independently controlled supports allowing for the safe placement on the ground.

AVAILABILITY

One Unit available for sale in Europe.

DIMENSIONS

- Lenght : 16000mm

- Width : 2550mm

- Height : 3480mm

UNIT FOR SALE

ONE UNIT AVAILABLE IN EUROPE.

All Belt Conveyor - Dualbelt 3000

Convey-All Belt Conveyor Model Dualbelt-3000 is a trailer-mounted fracturing unit designed to deliver proppant from sand movers to blender.

A double belt conveyor (Dualbelt) is a unit which is used by in the situation of multi-stage hydraulic fracturing. It happens when the amount of required proppant is greater than possibility of its storage in the SK-2000 or SK-3000 Sand Movers. Belt conveyor is powered by Caterpillar Diesel Engine Model C4-4 and allows to move the proppant at speeds up to 24 000 lbs/min (~11 tons/min).

MAIN COMPONENTS

- Deck Engine: CAT C4-4, rated 130 BHP

- Efficiency : The rate of bulk material transfer - 24000 lbs/min (~1 tons/min)

- Support System : Dual Belt Conveyorr has four independently controlled supports allowing for the safe placement on the ground.

AVAILABILITY

One Unit available for sale in Europe.

DIMENSIONS

- Lenght : 16000mm

- Width : 2550mm

- Height : 3480mm

UNIT FOR SALE

ONE UNIT AVAILABLE IN EUROPE.

Sand Conveyor Belt

The Uni-Belt unit is designed to convey product from multiple storage location to blender at a controlled delivery rate.

The design of the unit will allow up to 6 sand trucks, sand silos or sand kings to be positioned to deliver sand to the blender simultaneously.

The delivery rate is controlled by the speed of the sand delivery to the belt or by the speed of the belt to the blender.

This unit is designed to work in harsh conditions and easily transportable from one job site to another.

TECHNICAL SPECIFICATIONS

- Diesel Engine: CAT C4.4

- Load per axle : 6.1t

- Unit weight : 8.8t without any load

- Discharge rate : 18000 lbs/min

AVAILABILITY

1 Unit available in Europe.

DIMENSIONS

- Lenght : 16000mm

- Width : 2300mm

- Height : max. 3480mm (operational position)

- Height : max. 3660mm (transport position)

SAND CONVEYOR BELT FOR SALE

1 UNIT AVAILABLE IN EUROPE.

Frac Liquid Additive System

C.A.T. Construction (actual GOES GmbH) LAS trailer-mounted unit is used to pump liquid chemicals during hydraulic fracturing operations. The main task of the unit is to precisely add and measure the amount of liquid chemical additives in real time during the hydraulic fracturing job.

LAS unit has an insulated compartment to house 10 tote chemical tanks for 2640 gallons of chemical storage capacity. All tanks are suitable to be loaded/unloaded by forklift, and all of them are equipped with level indicators and additional level control system with display on control panel in operator’s cabin. Four tanks are equipped with stainless steel mixers. LAS is equipped with ten chemical injection pump systems, two transfer pumps and one centrifugal pump. The chemical additive pumps are electrically driven and provide failure-free injection of chemical additives. The metering system includes Coriolis flowmeters enabling accurate measurement of each chemical liquid additive injected. The discharge of each pump is fitted with a 75’ (~23m) chemical hose. Additionally, the unit is equipped with a Gorman-Rupp centrifugal pump, capable of pumping at 40 bpm.

MAIN COMPONENTS

- Deck Engine: John Deere model 4045HF120; Power : 100kW; Unit is equipped with generator

- Controlling : Automatically from the U-DAC (AccuFracTM module) or Manually from the operator’s panel

- Liquid Chemical System : Waukesha and Roper Pumps

- Centrifugal Pump : Gorman - Rupp 6"x6"

- Transfer Pumps : 2 progressive cavity pumps

- Measurement system : Each IBC pallet has an electronic level indicator, coupled with operator’s cabin; Coriolis flowmeters on the discharge of each chemical pump

AVAILABILITY

One Unit available for sale in Europe.

DIMENSIONS

- Lenght : 13000mm

- Width : 2550mm

- Height : 4000mm

UNIT FOR SALE

ONE UNIT AVAILABLE IN EUROPE.

Water Tank Trailer

The Eurotech thermoisolated water tank is a trailer mounted Units designed hold heated fracturing liquid in harsh oilfield environments.

This unit is capable of operating in an ambient temperature range of -40°C to +50°C.

MAIN COMPONENTS

- Capacity : 400 BLL

- Thermoisolation : Yes

AVAILABILITY

Multiple units available for sale in Europe.

DIMENSIONS

- Lenght : 12500mm

- Width : 2500mm

- Height : 4000mm

- Empty weight : 14.000 kg

UNIT FOR SALE

MULTIPLE UNITS AVAILABLE IN EUROPE.

Acid Tank

Manufacturer – Trokotex Polymer Group Sp. z.o.o.

Manufacturing Year – 2013

MAIN COMPONENTS

- Capacity : 24 m3

- Liquid type : HCL

- Boost pump electric driven

AVAILABILITY

One unit available for sale in Europe.

DIMENSIONS

- Lenght : 14000mm

- Width : 2450mm

- Height : 3200mm

- Empty weight : 17500 kg

UNIT FOR SALE

MULTIPLE UNITS AVAILABLE IN EUROPE.

Frac Iron Trailers (set of three units)

TECHNICAL SPECIFICATIONS

TRAILER 1

- SPM Swivel Joint, Fig. 1502-3" - 216 pcs

- SPM INTEGRAL Pipe, Length 2', 3" - 11 pcs

- SPM INTEGRAL Pipe, Length 4', 3" - 58 pcs

- SPM INTEGRAL Pipe, Length 6', 3" - 20 pcs

- SPM INTEGRAL Pipe, Length 10', 3" - 30 pcs

- SPM INTEGRAL Pipe, Length 15', 3" - 10 pcs

TRAILER 2

- SPM Swivel Joint, Fig. 1502-4" - 87 pcs

- SPM INTEGRAL Pipe, Length 2', 4" - 10 pcs

- SPM INTEGRAL Pipe, Length 4', 4" - 34 pcs

- SPM INTEGRAL Pipe, Length 10', 4" - 45 pcs

TRAILER 3

- SPM Valve, valve flapper type, Fig. 1502-3" - 10 pcs

- SPM Valve, valve flapper type, Fig. 1502-4" - 8 pcs

- Plug Valve Fig. 1502-3" - 7 pcs

- SPM Crossover Fig. 1502-3" - Fig. 1502-4" M/F - 19 pcs

- SPM Bull Plug Assy Fig. 1502-3" M/F - 33 pcs

- SPM Bull Plug Assy Fig. 1502-4" M/F - 20 pcs

- SPM Ball Injector Fig. 1502 - 3" - 2 pcs

- SPM Tee piece, Fig. 1502 - 4" x 4" x 2" M/F - 47 pcs

- SPM Lateral, Fig. 1502 - 4" x 4" x3" M/F - 18 pcs

AVAILABILITY

3 Units available in Europe.

DIMENSIONS

- Lenght : 12500mm

- Width : 2500mm

- Height : 4000mm

UNIT FOR RENT

3 UNITS AVAILABLE FOR SALE IN EUROPE.

Coiled Tubing Tool Package

Coiled Tubing Tool Container

Workshop Container with wide assortment of lightly used downhole tools suitable for Milling & Jetting Operations. Tools are mainly 1-11/16 and 2-1/8” OD used on 1-1/2” & 1-3/4” Coiled Tubing Units.

Package also includes connector installation tool & full range of redress kits. European Tool Manufacturer. Please contact for complete inventory & pricing.

AVAILABILITY

1 Unit available in Europe.

COILED TUBING TOOL CONTAINER FOR SALE

1 UNIT AVAILABLE IN EUROPE.

Acid Frac Tanks

This carbon steel tank trailer is designed to store acid, water for frac sites or groundwater remediation projects. It is easy to move, clean and suitable to store 83 m³ of liquid.

TECHNICAL SPECIFICATIONS

- According E.E.C Rules

AVAILABILITY

2 Units available in Europe.

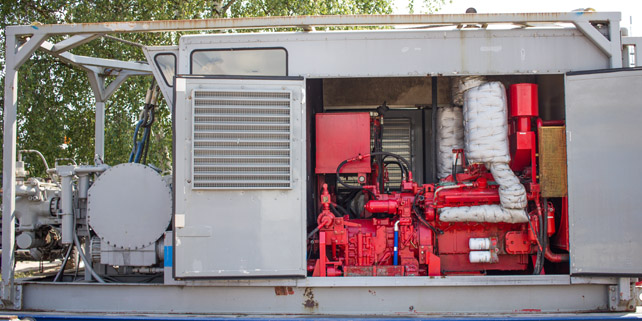

Twin Pump Skid

This “Serviced/Tested” Skid Mounted Twin Pumping Unit is suitable for onshore/offshore operations.

MAIN COMPONENTS

- Carrier – Heavy Duty Skid / protection frame

- Cabin – Two Rooms, Insulated

- Deck Engines – 2 DDC 12V71

- Deck Transmissions – 2 Allison CLT 6061

AVAILABILITY

One Unit available in Europe.

- Cooling Systems – Vertical radiator with Mechanical Fan Drive HES HT400

- High Pressure pumps : 2 HES HT400

- Control Systems – Control Console with Local Controls, GOES DAS

UNIT FOR SALE

1 UNIT AVAILABLE IN EUROPE.

2.000 Gallons Nitrogen Storage Tanks

The skid mounted Nitrogen tank is Cryogenic Offshore Vessel, suitable for storage Nitrogen for easy operation and safety transportation.

FEATURES / APPLICATIONS

Inner vessel material: 304/304L stainless steel

Outer vessel material: ST52

Super insulation

NER (Normal Evaporation Rate): 0.60 N2% / day maximum

Third party certification available

DNV certified

OTHER CHARACTERISTICS

- Capacity: 8.4 m3

- Maximum Working Pressure: 3.1 bar

- Design pressure: 5.33 bar

- Design Temperature Inner Vessel: -196 °C

- Design Temperature Outer Vessel: +50 °C

- Design Ref. DNV 2.7-1 / EN 13458

DIMENSIONS

- Lenght : 3645 mm

- Width : 2435 mm

- Height : 2590 mm

- Weight : 29050 kg

AVAILABILITY

4 Units available in Europe.

SALE OR RENTAL

4 UNITS AVAILABLE IN EUROPE FOR SALE OR RENTAL.

Batch Mixer

2 x 10m³ Premix Tank

The 20 m³ Batch Mixer is available for rental/Sales in good conditions and with economical price, which is heavy-duty skid mounted for easy transportation and efficient cementing job

OTHER CHARACTERISTICS

- Electrically driven

- Mixing Paddles inside mixing tanks

- Charge pump: Mission

- All connections: WECO

- Circulation manifold included

- Tank: 2 x 10m²

- Bulk cement line: 3″

- Sunction line: 4″

- High Pressure line: 2″ 1502

AVAILABILITY

One Unit available in Europe.

UNIT SOLD OUT

THIS BATCH MIXER IS SOLD OUT, PLEASE REQUEST A QUOTE FOR A NEW UNIT.

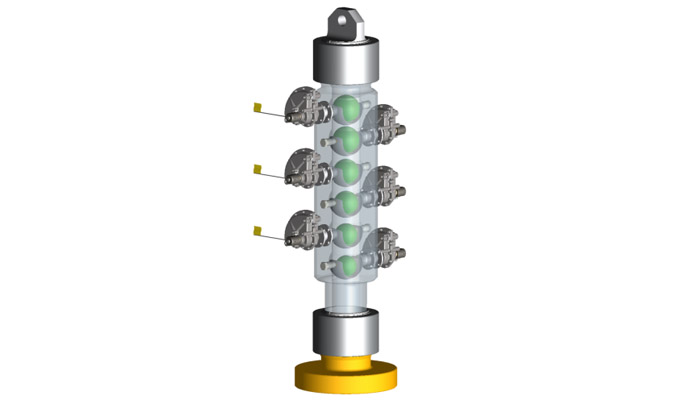

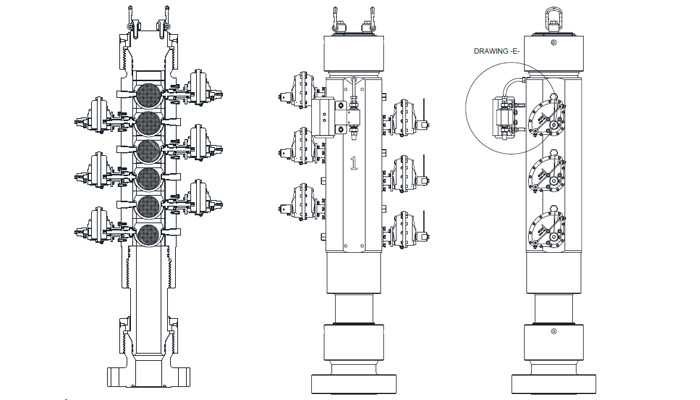

5-1/2” 15K Ball Launcher

The T-Frac Ball Launching System is a compactly designed high pressure device used in multi-zone fracturing operations such as the T-Frac system.

It provides an automated launching process to speed up and eliminate errors in the process of launching operating balls into the well undergoing treatment. It can handle a total of 6 separate balls in sequence and if more are required, the units can be readily staced as required.

Each ball is launched remotely using a proven quarter turn pneumatic actuator operated from a self-contained control panel. The ball launcher incorporates both a flad indicator to give visual indication of launching an a manual override should it be required.

MAIN COMPONENTS

- It Includes :

- Qty 6, 100ft air hose and associated fittings

- Control Panel

- Skid

- Air Compressor (Diesel)

- Nitrogen system (Tank)

- Tool Box

- Size: 5 1/2″

- ID: 5,000″

- Ball sizes: 1,250″ – 4.750″

- Pressure rating: 15 000,00 psi

- Ball Launch Capacity: 6 pcs

- Lower Flange Connection: 5-1/8″ 15M w/ BX-169

- Crossover Flange: 5-1/8″ 15M w/ BX-169 (Up) x 3-1/16” 15М (Down) w/ BX 154

AVAILABILITY

One Unit available in Europe.

UNIT FOR SALE

1 UNIT AVAILABLE IN EUROPE.

HIGH RATE HEATING UNIT

Heating up to 7 million BTU

Carrier Vehicle

Compact SKID mounted with operator cabin

This high rate heating unit is designed to heat and pump various fluids used in harsh oilfield operation. It equipped with mission pump for circulating, Roper pump for transferring and operator cabin.

This unit is available for rental now.

MAIN COMPONENTS

Diesel engine : CAT 90HP C4.4

Centrifugal Pump : Mission 4“x5“

Loading Pump : Roper 3“

Heater : 7 million BTU

Fuel Tanks : 5000L

FEATURES / APPLICATIONS

Compact design for efficient operation

Heating capacity : 7 million BTU (2050kW/hr)

90 m 3 / hour heating ( from 5 o c to 23 o c)

Heated operator cabin

Circulate rate: +/- 200L / min

UNIT FOR RENT

1 UNIT AVAILABLE FOR RENT IN EUROPE.

WATER FILTERING UNIT

Heavy-duty SKID for filtering 40-60 m3 / hour

The SKID mounted filter unit is compact skid design for filtering water on oilfield service.

The unit is equipped with diesel engine. It’s available for rental now.

Carrier Skid

Heavy Duty SKID Frame

MAIN COMPONENTS

Diesel Engine: 24kW Hatz

Centrifugal Pump: Type R27-125S-270

Secondary Filter: 2 / 5 microns

Manifold: 6 pcs

Butterfly Valve: 4“

FEATURES / APPLICATIONS

Transport on trailer or flatbed truck

24kW Hatz diesel motor

Parallel, double pod design for efficient opperation

Choice of different filters avaliable

Up to 60 m3/ hour filtering capacity (with clean source water)

Reservation place for hoses

Toolbox

DIMENSIONS

Lenght :3.000 mm / Width : 1.800mm

UNIT FOR RENT

1 UNIT AVAILABLE FOR RENT IN EUROPE.

HEATING & FILTERING UNIT

3.5 million BTU Heater +90 m3 / hour Filtering

The combination heating & filtering unit is a combination design to treatment of oilfield water for both: filter and heat.

The unit can work as heater alone, filter alone, or combination of heater and filter. This unit is available for rental now.

Carrier Vehicle

Compact Chassis: Mercedes-Benz 4 x 4

Emission: Euro IV

MAIN COMPONENTS

Heater: Gentex 35M Texheater

Filters: 1-5 micron

FEATURES / APPLICATIONS

Parallel, double pod design for efficient operation

90 m3/hr filtering with normal field water

3.5 million BTU (1.025 kW/hr) heater unit

45 M3/hr heating (from 2o C to 20o C)

Engine pre-heating

DIMENSIONS

Lenght : 6.014 mm / Width: 2.417mm / Height: 2.853 mm

UNIT FOR RENT

1 UNIT AVAILABLE FOR RENT IN EUROPE.