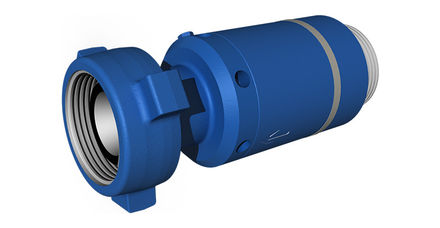

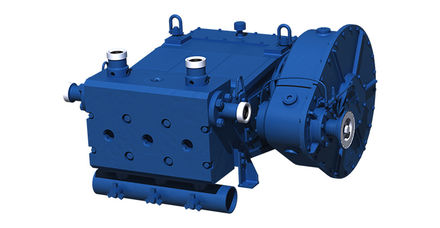

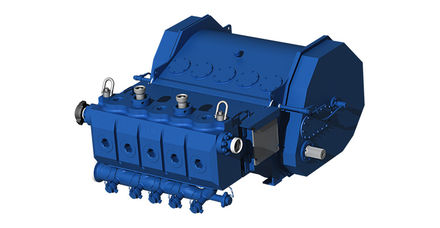

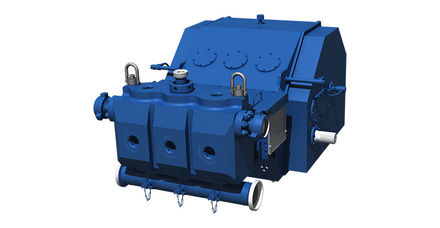

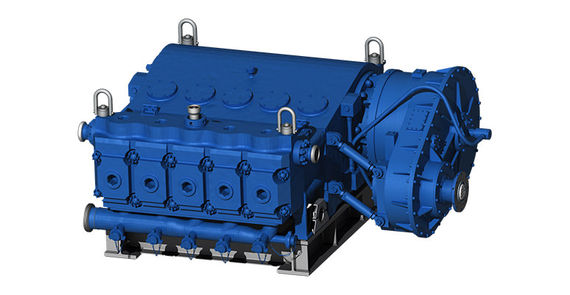

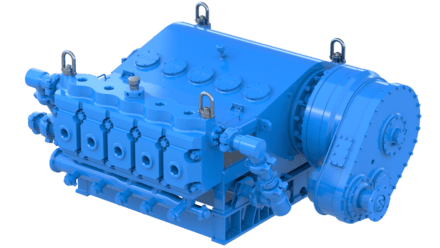

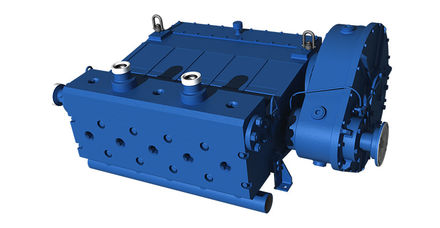

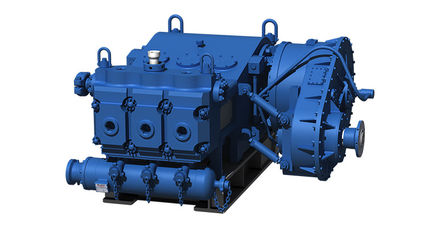

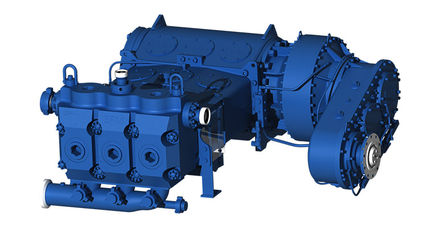

SPM Oil & Gas leveraged our nearly 150-year legacy of engineering excellence and the precision engineering of the proven SPM® QEM platform—with zero NPT reported in more than a billion field cycles—to design a heavy-duty, high-horsepower frac pump built to run at 100% of rod load, 24 hours a day—and it’s built for electric, too.

The SPM® QEM 5000 E-Frac Pump answers industry demand for longer hours of operation,

offering extreme durability and total system cost reduction in a cleaner package.

Its compatibility with electric motors and gas turbines, means the SPM® QEM 5000 E-Frac Pump enables lower fuel spend and fewer overall assets on location. The pump’s high capacity and durability are designed to reduce downtime, lower total cost of ownership, and improve your bottom line.